Transformation. It’s not a word to be used lightly. It oftentimes includes a dramatic change, and sometimes a complete metamorphosis.

When a transformation takes place, it’s typically needed.

The threats our warfighters face while completing their missions continue to evolve in complexity, scale, and severity. They need the right tools to complete their mission and come home safely.

Lockheed Martin is transforming the business to ensure the warfighter is prepared for those ever-evolving missions with tools that match.

Two of those tools include the Joint Air-to-Surface Standoff Missile (JASSM) for the United States Air Force, and the Long-Range Anti-Ship Missile (LRASM) for the United States Navy.

While JASSM has been in service for many years, it is still relevant to the warfighter today. LRASM, a fairly new cruise missile variant, continues to witness increased demands due to its unique capabilities. Both cruise missiles are anticipated to be essential to the warfighter for years to come.

How do we ensure cruise missiles remain relevant? With transformation that is driven by the mission.

Evolving the Cruise Missile to Meet the Need

With the introduction of StarDrive to speed up the development process and digital techniques applied to start-up programs such as the Stand-in Attack Weapon (SiAW), Lockheed Martin has embarked on an transformation journey with every facet of the business, including products in different life-cycle stages.

Accelerating the delivery of advanced capabilities to the warfighter is one of Lockheed Martin’s highest priorities and our Model-Based Enterprise (MBE) is key to getting us there.

With an MBE, we will provide our customers with an integrated digital environment that spans the entire life cycle of a program, including adding upgradeable product improvements to existing programs – such as JASSM and LRASM – to further their lifespan.

To do this, we are partnering with our customers to smartly incorporate digital engineering tools and tapping into the modeling and simulation data we’ve acquired for over 40 years of experience with missiles to evolve these products much more quickly and affordably. By implementing advanced modeling, simulation and machine learning, as well as software factories, we have more flexibility to upgrade the munitions through incremental, rapid, and continuous evolution.

Each time we perform a flight test–whether in the field or in the lab–we compare real data to projected data and update the calculations to improve the system. This helps ensure the actual test performance meets or exceeds requirements, which further improves development costs and accelerates schedules.

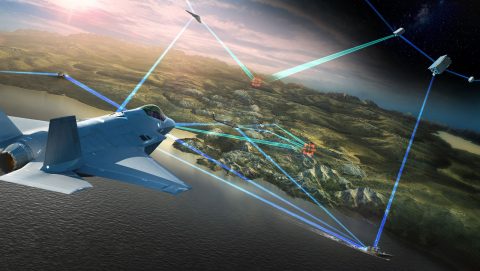

These approaches and tools help to not only improve on the systems themselves, but also discover ways of integrating the systems onto new platforms, such as the F-35.

Integrating JASSM, LRASM and new technologies onto the F-35 suite continues to increase multi-role mission capabilities – helping to continue to make the F-35 the most lethal, stealthy and survivable aircraft in the world.

In addition to F-35 integration, we’re investing in the continued design and development of LRASM, which includes surface-launched variants to support the U.S. Navy’s ‘Distributed Lethality’ concept.

The LRASM surface-launched variants include a vertical launch system, the design of a topside (or deck-mounted) launcher configuration for integration on multiple surface ships, and a mobile-launcher variant that will provide forward-based ground forces an anti-surface weapon capability.

Digital Tools in Production Factories

As a part of process automation, we are digitally simulating the manufacturing environment to increase downstream efficiency to automatically capture design specifications and content for inspection planning to integrate those product enhancements into the next iterations much more quickly.

We leverage the same production line on JASSM and LRASM, which provides tremendous opportunities to reduce time, risk and cost.

In June, we opened a new 225,000-square-foot production facility with dynamic factory model forecasting, a fully-robotic paint line, and more automated processes. Factories like these will empower our talented workforce to not only produce these systems more quickly, but also allow them to insert new ideas into the evolution process as well.

The new intelligent factory is in addition to our current production facilities that have delivered nearly 4,000 JASSMs and LRASMs to our customers to date.

We’re transforming across the enterprise. The digital engineering, advanced modeling and simulation, model-based approach, software factories, intelligent manufacturing facilities, and our people, will allow us to produce these systems at high capacities while simultaneously evolving the product to increase capabilities.

To learn more about Lockheed Martin’s digital transformation efforts, visit: mission-driven transformation website.

About the Author

Jay Pitman

Air Dominance & Strike Weapons Vice President

Jay oversees Lockheed Martin Missiles and Fire Control’s Air Dominance and Strike Weapons line of business which includes JASSM, LRASM, and Hypersonic Strike Systems.